DESIGN WITH RECLÉM

RECLÉM RESCUES TEXTILE WASTE

Rescuing textile waste with RECLÉM’s patented method not only revolutionizes the way that designers can design products, but it also restructures the textile goods production process.

BREAKING FROM THE STATUS QUO

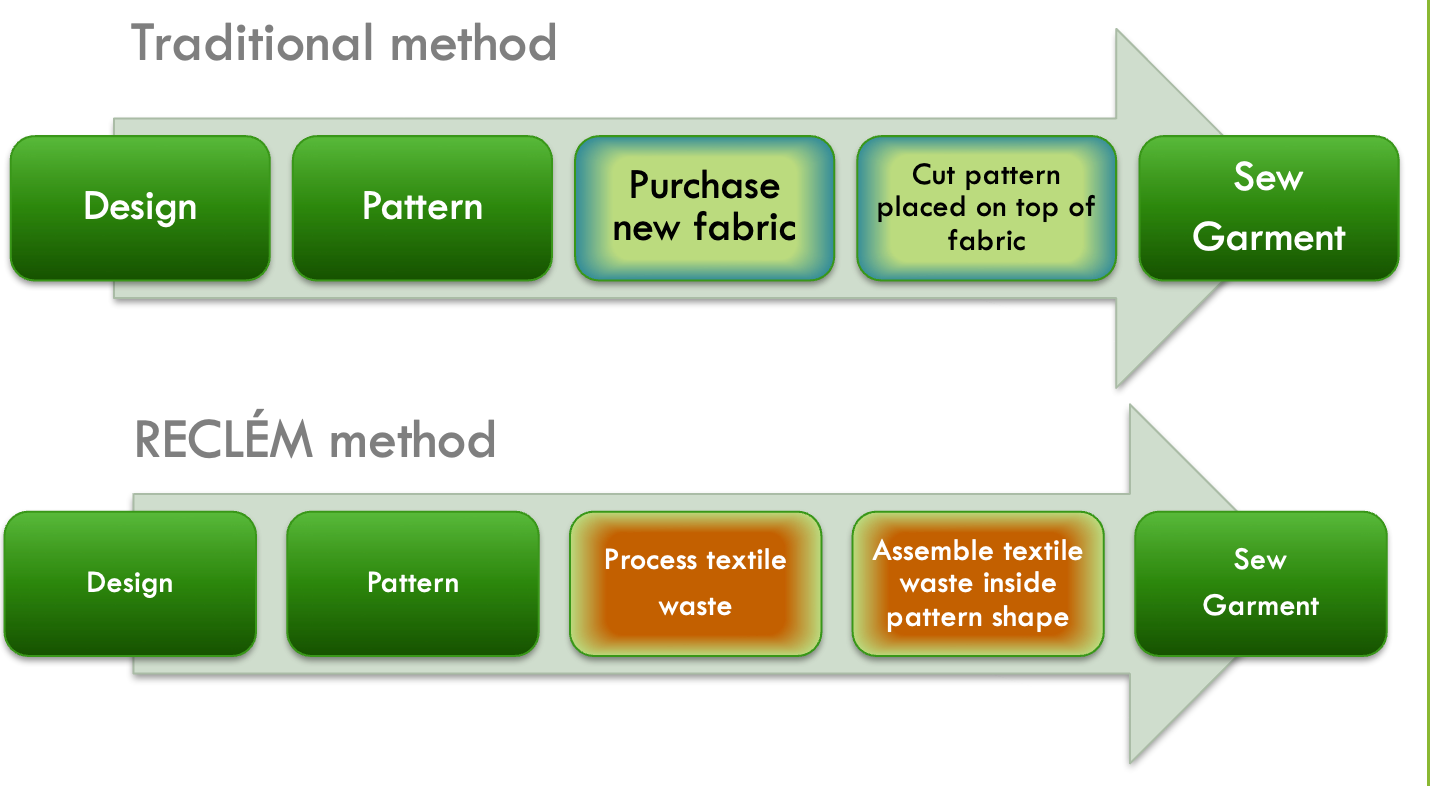

For over 100 years, the traditional method below has been a standard for industrial design and production of textile goods. The RECLÉM rescue textile waste method is shaking up that arrangement. It keeps part of the traditional process and replaces two key phases – exchanging purchasing new fabric for processing textile waste, and instead of cutting the pattern placed on top of the fabric, the RECLÉM rescue textile waste method allows the designer to create a new textile by “painting” with textile waste inside of the pattern shape.

What takes RECLEM’s rescue textile waste process from craft to industrial applications?

Reinvents the textile supply chain

- Traditional manufacturing; new material = over 50% of apparel cost

- RECLÉM manufacturing; NO new material = Save cost & energy, lower carbon footprint

Reinvents the textile supply chain

- Average standard waste for apparel production markers ranges from 10% to 25% of material.

- Material is only placed inside the shape of the pattern pieces creating zero waste.

Maintains scalable product production.

- Cutting in quantity

- Automated stitching

- Marker 12’ wide and over 20 yards long

- Standardized for mass production

- Reproducible colorways & sizes

How would one accomplish all of these great things, you might ask?

Contact us to discuss:

- We collaborate with designers and manufacturers

- We license our patented method

- We consult with companies to improve the sustainability of their current manufacturing process.

Collect - textiles from cutting waste, unwanted clothing and textiles and dead stock fabric.

Process textiles *Unwanted clothing and textiles should be laundered before handling.

Stitching can be done freehand for 1 of 1 pieces, or automated on a sewing machine where the operator chooses the pattern, scales it to a desired density, and digitizes the shape of the pattern piece.

Finishing includes sewing, finishing edges, clipping threads, pressing, and overall quality control of the product.

Washing the stitched layers results in the biodegradable substrate disappearing and leaving a new and unique fabric.